China-Techpart Precision Technology Co., Ltd (short as

China-Techpart) is professional international export

company which specialized in producing conveyor belt roller

punching press bearing housing and relative

sealing. China-Techpart business have extended all over the

world such as Mexico, Russia, Chile, Brazil, UK,

USA etc, which have established good relationship with famous

customers in main countries and region of the

world. Our global market share is growing bigger and bigger.

China-Techpart already received highest recognition

more than 50 countries and over 200 customers with highest quality

and professional service which is the cornerstone

of rapid expansion in the international market

China-Techpart wholly owned holding company which have 4 advanced

technology punching press production

lines, high precision injection production center, as well as

modern mould machining center. Now China-Techpart

is China's largest and most complete varieties professional

punching press bearing housing and sealing parts

manufacturing. China-Techpart's production ability over 5 million

sets of bearing housing annually, All export

products will be checked by equipments imported from Italy, the

tolerance is accurate to 0.001mm, which ensure

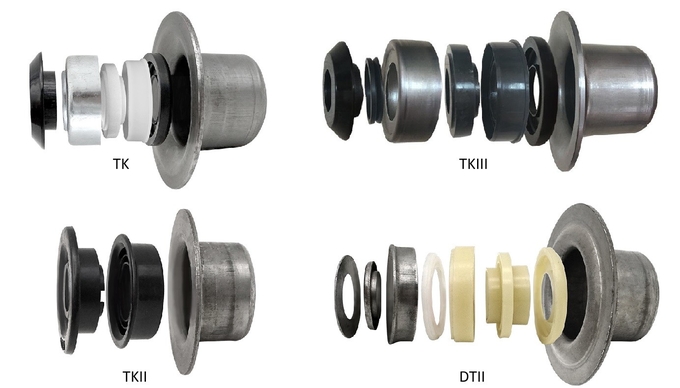

the products diamonds quality. China-Techpart can supply belt

conveyor roller bearing housing and sealing type such

as TK, TKII, and DTII etc. China-Techpart also can produce in

according with your exact requests.

China-Techpart's bearing housings is not only the indispensable

parts of common conveyor roller manufacture, but

also the preferred products chosen by roller manufacture with

high-speed, long-distance and large capacity transportation,

which can be widely used in the national major projects as mine,

steel, cement, coal, electric power and seaport industry.

The advantages of China-Techpart roller bearing housing and

relative sealing are following:

Ø Excellent material. The material are used cold rolled sheet from

Bao steel Co., Ltd, Wuhan Iron & Steel Corp

Ø Fatigue resistance, no deformation and no distortion

Ø Good Polish effect, no stretching scars and burrs

Ø High precision, low eccentricity

Adhering to the principle of "develop together with grateful heart

and contribute society endlessly", China-Techpart

holds the hope that we work together to create brilliant future

with high-quality product, reasonable price and best

service. China-Techpart focus on a strategic further, for build

company unique "China-techpart" world brand. Our

goal is to make the "China-techpart" as the Chinese bearing housing

appellation.

China-Techpart unique business goal:

Make "China-techpart" to be landmark brand of China bearing housing

around world market.